Using MAX Impact Power moles is a very reasonable alternative to laying installations in trenches.

Our trenchless tools offer considerable benefits:

· time savings

· cost savings

· minimising traffic disturbances (detours, closed lanes)

· eliminating the costs of road cutting and repaving

· ensuring highest quality of construction works and environmental protection (plants, trees, gardens, low noise levels, no exhaust fumes)

· smaller dependence on weather

· crew limited to 2 people plus a compressor

· minimising inconvenience for local communities

Trenchless technology machines make it possible to reduce the costs related to laying all types of installations (water, power, natural gas, telecommunications) and speed up the construction work. Typically the engineer responsible for all the installations, the investor or property manager specify that cables and pipes running under roads or major streets should be installed by means of trenchless technologies. However in case of smaller lanes, walkways, lawns or gardens installations are often run in trenches. And this is where a trenchless method should be considered as it is much quicker, easier and cheaper. Just consider the cost of digging across the street, cutting and removing the pavement and then refilling the trench, compacting the soil and repaving. This cost would be further increased by road closure and arranging detours, which frequently involves a team of several people with a lot of equipment for a whole day. On the other hand a borehole made with a pneumatic impact mole could be performed in such locations by two people within one hour without any traffic disturbances. The same is true in case of lawns, gardens or public squares paved with setts, where restoring the original condition after trenching could be even more difficult

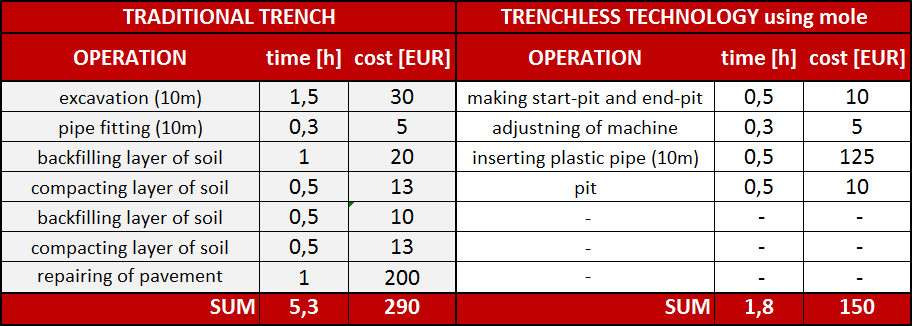

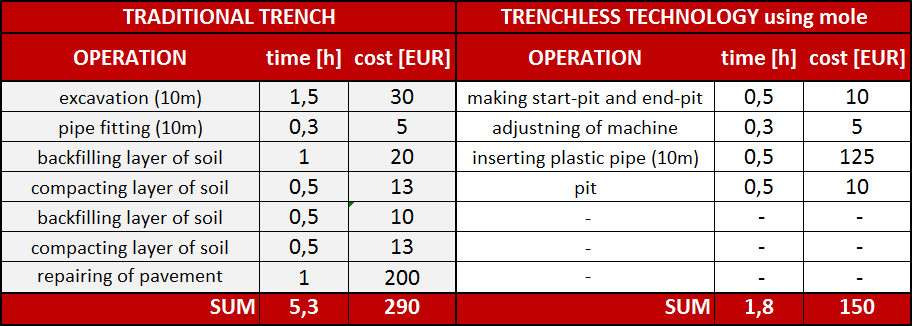

On the table below is shown the benefits: saving money and saving time, when we compare traditional trench technology with technology using pneumatic ground rockets.

|  Search

Search  Page map

Page map  E-mail

E-mail  Privacy policy

Privacy policy  Privacy policy |

Privacy policy |

back

back