The employees of the Municipal Water and Sewerage Company, before they decided to buy our ground rockets, wanted to make sure that they would meet their expectations. The company makes GRAVITY INSTALLATION, pipes diameter 110 mm and 160 mm. They decided to use MAX K130S Set with Calibrator Ø180 mm.

The installation took place in Włocławek, Poland.

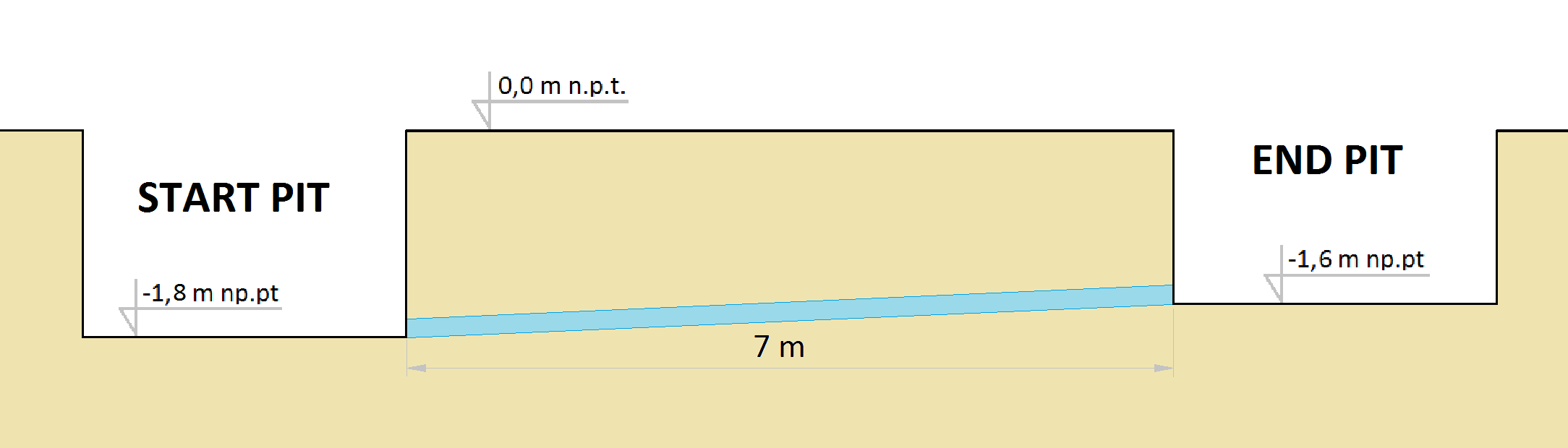

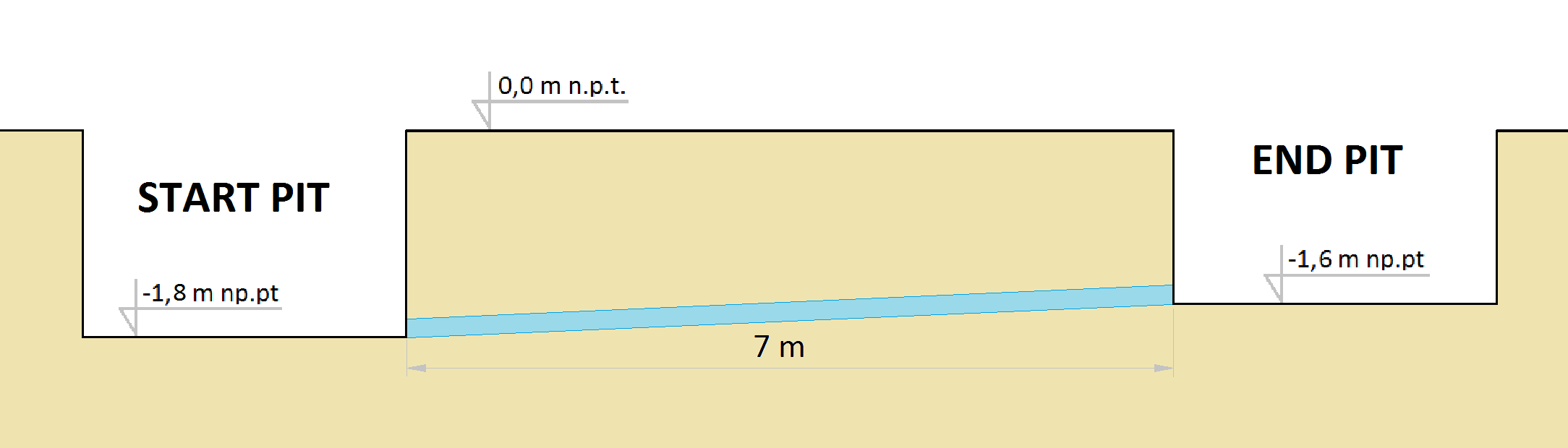

There were two gravity installations to perform, both PVC pipes diameter 160 mm, both 7 metres of length. The installation was made of pipes 1 meter of diameter each.

Two Start Pits (3x2 m, depth 1,8 m) and two End Pits (2x2 m, depth 1,6m) were made.

The gravitational decrease in this case was about 3% (less than 3 cm per 1 meter of installation.

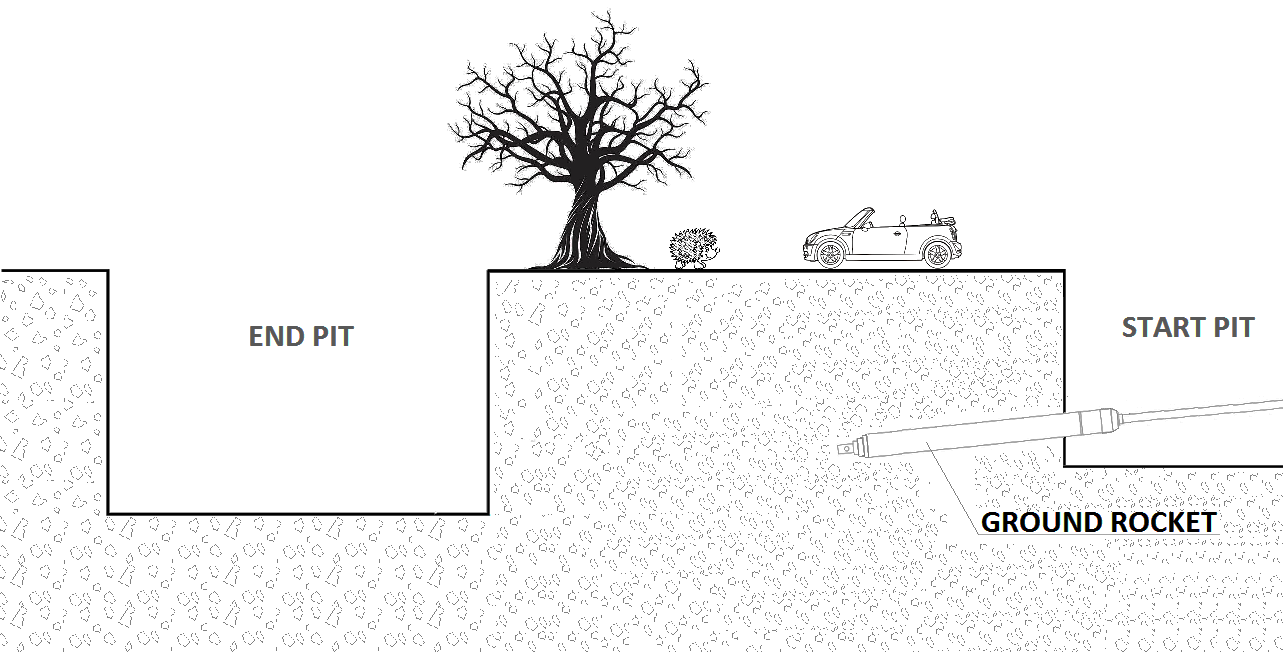

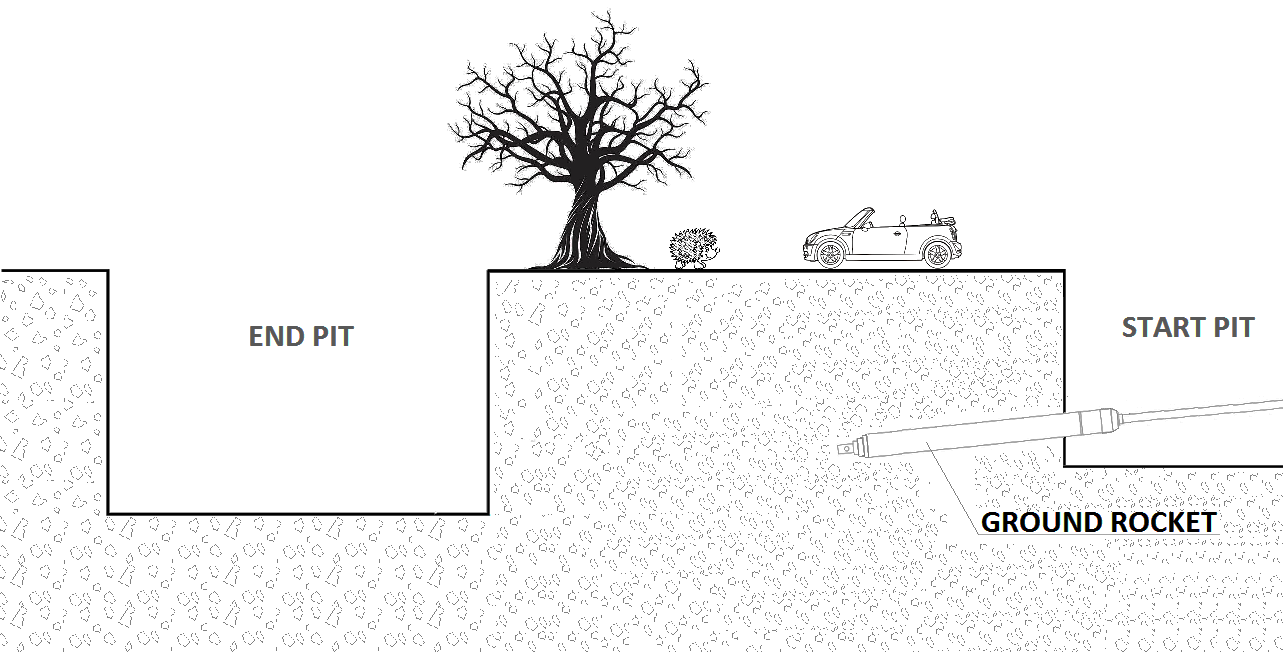

A starting hole was made, 3 metres of length, because the MAX K130S length is about 2 metres.

During the installation, the employees of MPWiK Włocławek were trained in the use of the machine.

Using the excavator, the mole was placed in Start Pit.

The making an installation using calibrator, requires two operation:

- making a pilot diameter 130 mm using only MAX K130S

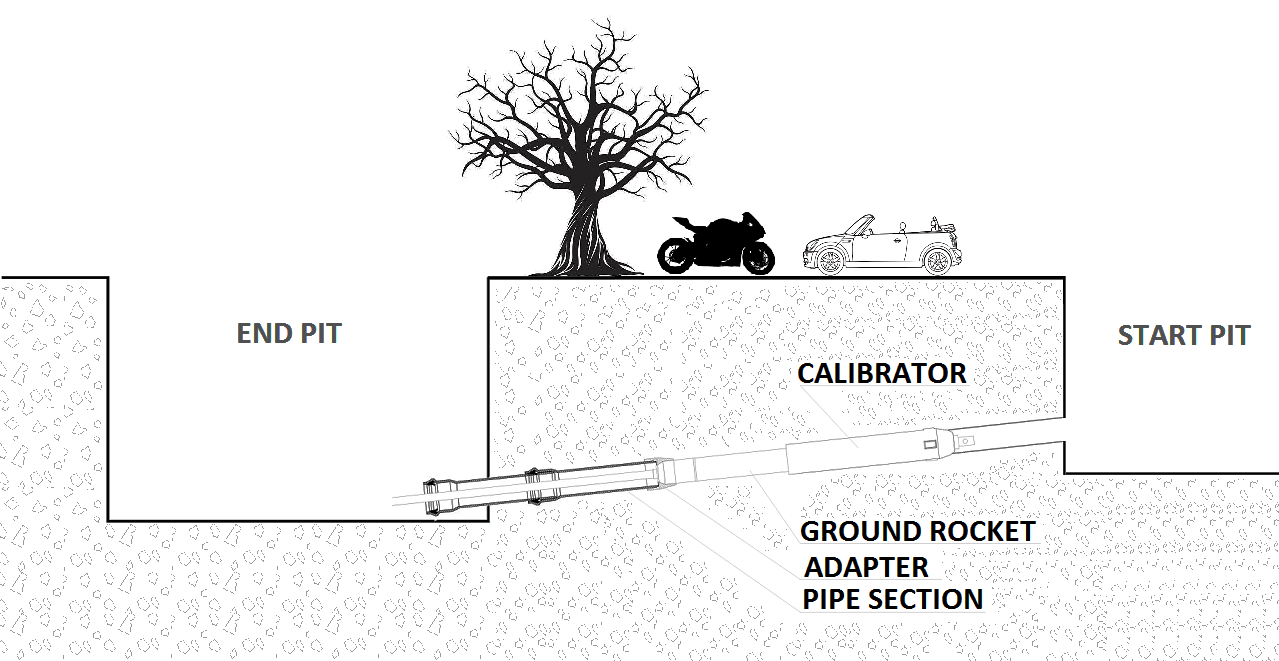

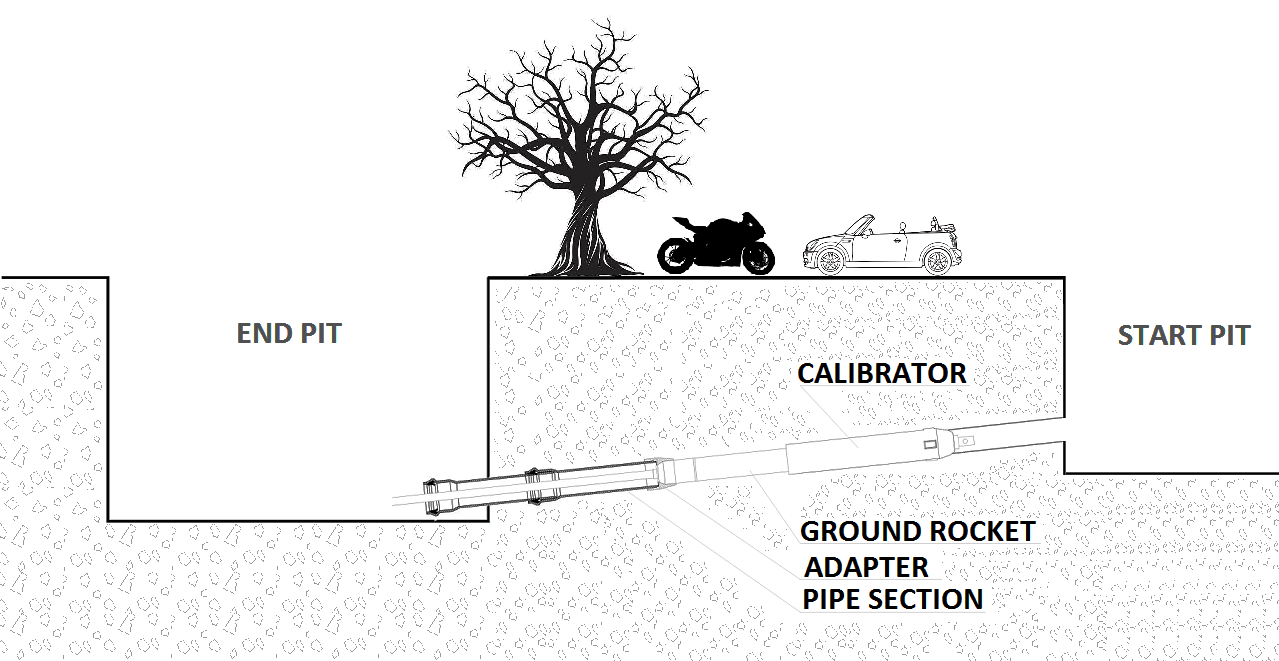

- widening the hole using Calibrator Ø180 mm with simultaneous pulling PVC pipe.

The first operation - making a pilot - hole Ø130 mm.

Both pilot installation were done accurately and efficiently. The execution time of both was 30 minutes.

Both installations had to be made of pipes Ø160 mm with a socket Ø180, from sections of pipes of a 1 meter length.

The Ground rocket has been equipped with Calibrator. Then the pipe segments were mounted to mole.

The pipes were installed segment by segment.

Good machines allow for precise gravity installations, sewage connections.

The material was made with the participation of MPWiK Włocławek.

BACK |  Search

Search  Page map

Page map  E-mail

E-mail  Privacy policy

Privacy policy  Privacy policy |

Privacy policy |

back

back